HYDRAULIC STRAINER If you're in search of hydraulic equipment that will help prevent obstructions and damage to your hydraulic pumps, look no further than the Hydraulic Suction Strainer. Filtration is essential for the durability of a hydraulic system, and a suction strainer is a key component in a wide variety of industrial operations. It is us...

HYDRAULIC STRAINER

If you're in search of hydraulic equipment that will help prevent obstructions and damage to your hydraulic pumps, look no further than the Hydraulic Suction Strainer. Filtration is essential for the durability of a hydraulic system, and a suction strainer is a key component in a wide variety of industrial operations. It is used to protect pumps and hydraulic circuits from debris and other particles that can cause damage or reduce their efficiency.

WHAT IS A SUCTION STRAINER ?

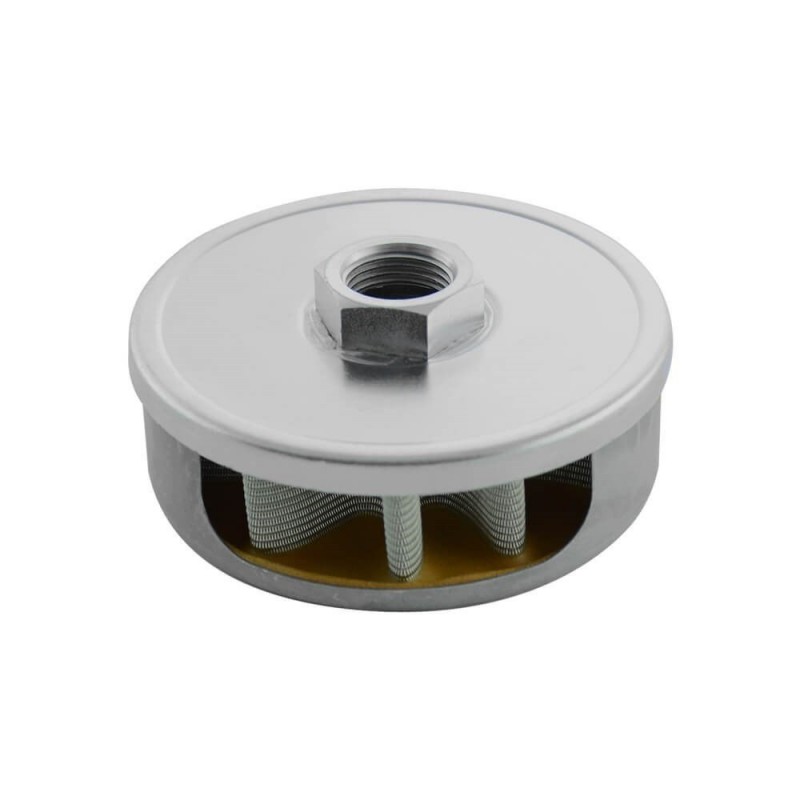

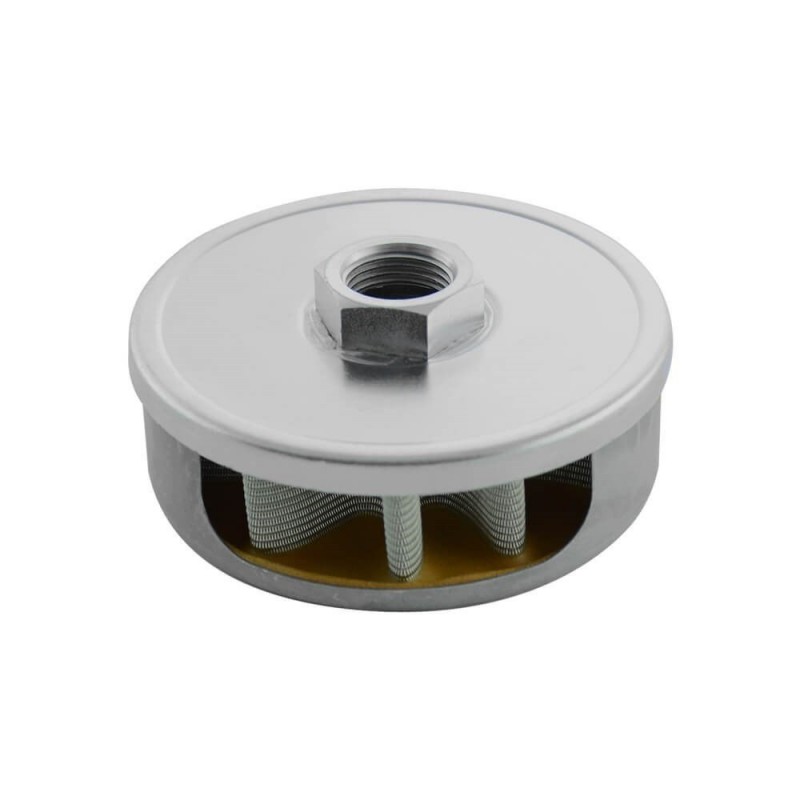

The hydraulic suction strainer is a vital element in many filtration and pumping systems. A hydraulic strainer is a type of filter used to remove debris and other particles from pumped fluids. It prevents unwanted debris and particles from entering the system and causing damage to the equipment. In hydraulic pumps, the hydraulic suction strainer is employed to filter oil before it enters the pump mechanism. Typically located at the pump's suction end, it is designed to allow fluid circulation while retaining larger particles.

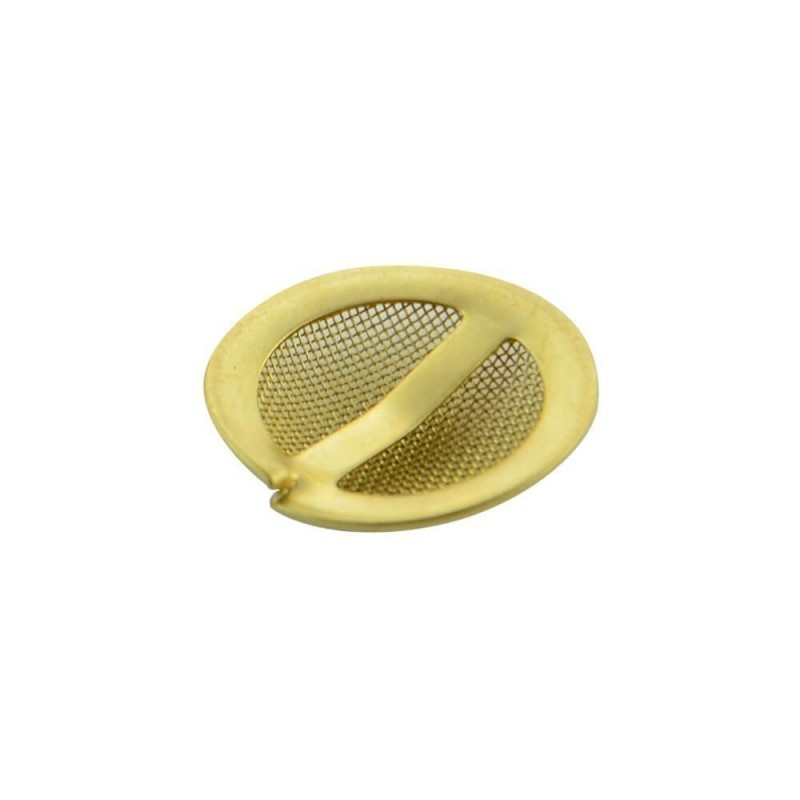

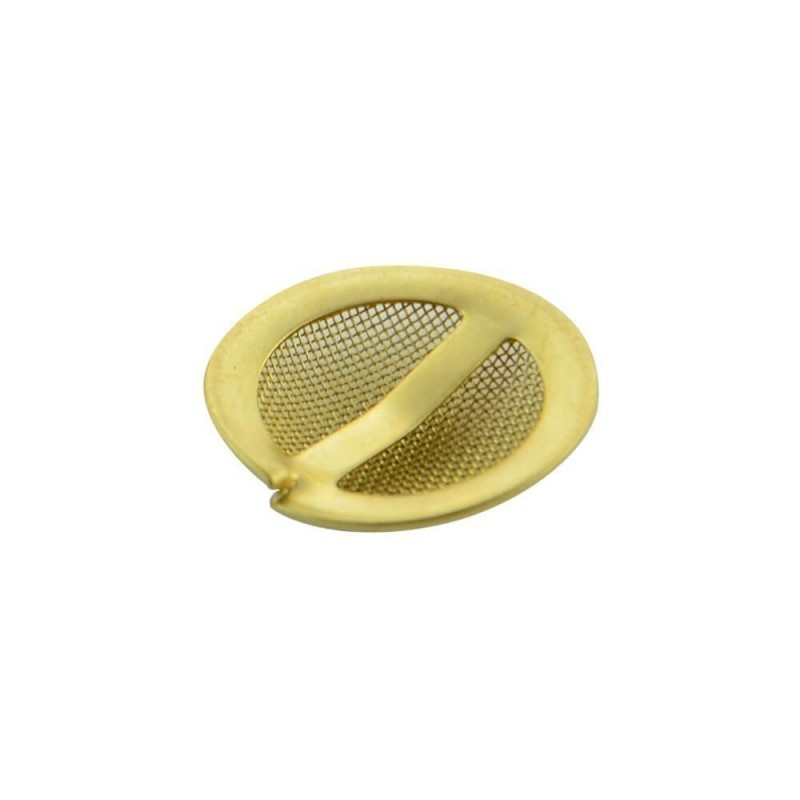

Hydraulic strainer are manufactured from various materials, including plastic, metal, rubber, and fabric. The material choice depends on the properties of the fluid to be filtered and the environmental conditions in which the pump will operate.

It's crucial to choose a suction strainer suitable for the hydraulic circuit and operating conditions. If the strainer is too fine, it may limit the liquid flow, leading to a drop in pump performance. Conversely, a strainer that is too coarse may not adequately filter the liquid, potentially causing pump damage. In conclusion, the hydraulic suction strainer is a critical element in filtration and pumping systems, protecting equipment from unwanted debris and particles, thereby extending its lifespan. It is important to choose a strainer tailored to the pump and operating conditions to ensure optimal system performance.

SUCTION STRAINER: OPERATION

How Hydraulic Suction Strainers Operate Hydraulic suction strainers operate by using a mesh screen or perforated plate to trap particles larger than the screen holes. As fluid passes through the strainer, debris is captured and prevented from entering the pump.

CHOOSING THE RIGHT STRAINER SIZE

When selecting a hydraulic suction strainer, size is a crucial factor. If the strainer is too small, it may quickly clog, leading to equipment failure. If it is too large, it may not effectively filter contaminants, allowing harmful particles into the hydraulic system. Therefore, accurately measuring the required strainer size for your equipment and choosing one that matches these dimensions is essential.

CHECKING FILTRATION

Capacity When choosing a hydraulic suction strainer, it's important to check its filtration capacity. This depends on the size of particles you want to filter and the pressure of your hydraulic system. Ensure you choose a strainer with sufficient filtration capacity to prevent blockages and damage to your equipment. Regularly cleaning your strainer is also important to maintain optimal filtration.

CONSIDERING MAINTENANCE AND CLEANING OPTIONS

When selecting a hydraulic suction strainer, consider maintenance and cleaning options. Some strainers can be easily cleaned without being removed from the equipment, while others require complete disassembly. Check if spare parts are readily available in case of need. Choose a strainer that offers convenient maintenance and cleaning options to ensure optimal operation of your hydraulic system.

TYPES OF SUCTION STRAINER FILTERS

There are several types of suction strainer filters, each designed for specific applications:

- Y-Strainers: Named for their Y-shaped design, these strainers trap particles at a 90-degree angle. Y-strainers are commonly used in applications with limited space, as they are compact and easy to install.

- Basket Strainers: These strainers have a basket-shaped filtering element used to trap particles. They are typically used in applications where a larger volume of fluid is pumped, as they can hold more debris before needing cleaning.

- T-Strainers: Similar to Y-strainers but with a T-shaped body, these are often used in applications where the pumped fluid has higher viscosity or when there is a higher risk of clogging.

- Conical Strainers: Designed with a conical shape, these strainers trap particles at the bottom. They are commonly used in applications with highly viscous fluids, such as oil or syrup.

MATERIALS USED IN HYDRAULIC SUCTION STRAINERS

Suction strainer can be made from a wide range of materials, depending on the specific application and the type of fluid being pumped. Stainless steel is a popular choice for hydraulic strainer because it is durable, corrosion-resistant, and easy to clean. Brass is another popular material for suction strainers, as it resists corrosion and can withstand high temperatures.

Hydraulic suction strainers are also manufactured in PVC, commonly used in applications where the pumped fluid is less aggressive and the strainer is not exposed to high temperatures or pressures. Additionally, polypropylene material is used in hydraulic strainers. Polypropylene strainers are lightweight and corrosion-resistant, making them a good choice for applications where weight and durability are important.

The material choice for your hydraulic strainer is crucial to ensure optimal operation of your hydraulic system. Stainless steel strainers are often preferred for their corrosion resistance and suitability for various environments. However, if your equipment operates in extreme conditions, such as high temperatures or corrosive chemicals, you may need to opt for a strainer made from specialized alloys to ensure a longer lifespan.

APPLICATIONS OF SUCTION STRAINER FILTERS

The Hydraulic Suction Strainer is used in various fields, including the oil industry, mining, food, and chemical industries. It is typically used to filter solids or impurities in liquids such as oil, petroleum, or chemicals. Hydraulic strainer are also employed in water wells to prevent debris or sediment from entering the pump, which can lead to equipment damage and a decrease in water quality. The suction strainer is a crucial element in the hydraulic field, protecting the pump from impurities present in the oil.

HOW TO USE A SUCTION STRAINER FILTER

- Choose the appropriate hydraulic suction strainer: The strainer size should match that of the pump, and the mesh should be fine enough to filter impurities without impeding water flow.

- Position the hydraulic strainer: It should be installed upstream of the pump, in the water, ensuring it remains submerged. The strainer's position should be chosen so that it is not obstructed by elements such as leaves, branches, or floating debris.

- Maintain the suction strainer filter: Regularly check and clean the strainer as needed to prevent impurities from accumulating and reducing water flow.

In summary, the suction strainer is a key element in protecting hydraulic pumps from impurities present in water. By following these steps, you can ensure that the strainer is correctly installed and maintained for optimal pump operation.

OCGF: OUR SELECTION OF SUCTION STRAINER FILTERS FOR SALE

OCGF is a company specialized in the sale of high-quality hydraulic suction strainers for various industries. For many years, OCGF has been committed to providing superior-quality products to its customers. OCGF's hydraulic suction strainers are designed to meet the strictest filtration requirements in challenging industrial environments. We offer an extensive range of strainer filters of all types. OCGF products are made from quality materials to ensure long life and exceptional reliability. Our suction strainer filters are used in a variety of industrial applications, including chemical plants, oil refineries, food processing, and pharmaceutical industries. They are designed.