Hydraulic Pressure Relief Valves: Protect Your Hydraulic System and EquipmentOur wide range of pressure control like hydraulic pressure relief valve provides an essential safety element in your hydraulic circuit. The pressure reducing must be fitted to any circuit, in order to protect the hydraulic pump which is its main component. The pressur...

Hydraulic Pressure Relief Valves: Protect Your Hydraulic System and Equipment

.jpg)

Our wide range of pressure control like hydraulic pressure relief valve provides an essential safety element in your hydraulic circuit. The pressure reducing must be fitted to any circuit, in order to protect the hydraulic pump which is its main component. The pressure relief valve on the hydraulic distributor provides protection for the various actuators, such as motors or single or double-acting hydraulic cylinders. Protect your distributor or your hydraulic pump from excess pressure and offer them greater longevity.

Hydraulic relief valve : how doest it work

Relief valve hydraulic behave like a valve in a hydraulic circuit. In the event of pressure above a determined value, they open and send part of the oil back to the tank. They are therefore an essential safety device to protect the hydraulic components, maximize their lifespan and avoid harmful consequences on the hydraulic circuit.

How pressure relief valve for hydraulic system work

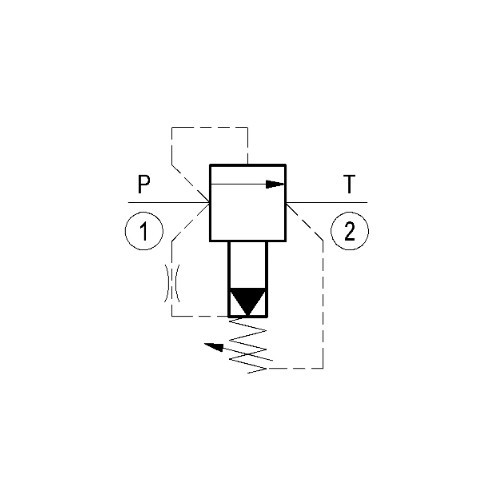

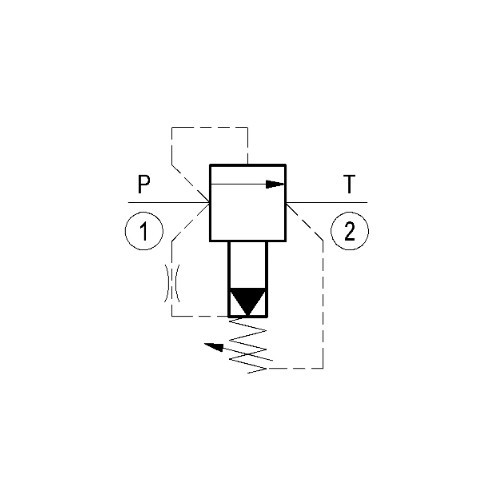

The pressure arrives through the inlet orifice also called the pilot orifice, it is brought to the valve which will be held closed and sealed by the spring. This valve will be located before the oil return orifice and will open when the pressure is high enough to overcome the force of the spring which holds the valve closed. The excess pressure present in the hydraulic circuit will end up in the return circuit and it is therefore routed to the hydraulic tank.

At rest, the valve is kept firmly closed by a spring. The liquid pressure is brought through a pilot orifice on the poppet, on the side opposite the spring. When the pressure reaches a sufficient value to overcome the force of the spring, the valve will open and let the oil escape: the return. Thus, the pressure will no longer exceed the spring calibration value.

The opening range of the pressure limiter

Some types of adjustable hydraulic pressure relief valve have an opening range. A low flow will lift the valve by slightly compressing the calibration spring, while a high flow will lift the valve by compressing the calibration spring more strongly, therefore the pressure read on the pump discharge will be higher. Care must therefore be taken to calibrate the hydraulic pressure limiter according to the nominal flow rate passing through it.

Calibration of a hydraulic pressure limiter

To avoid having a loss of flow through the pressure limiter, it must be calibrated to a value corresponding to the maximum load pressure + the opening range of the device for the pump flow. The derating of the pressure limiter must be done while still maintaining contact with the spring. In addition, some limiters, if they are derated too much, become blocked.

Thus, pressure relief valves, by regulating the flow of hydraulic fluid through a valve, provide additional safety. There are two types of pressure limiter:

- Direct acting pressure relief valve

- Pilot-operated pressure relief valve

The different types of action for hydraulic pressure relief valves

Direct acting pressure relief valve

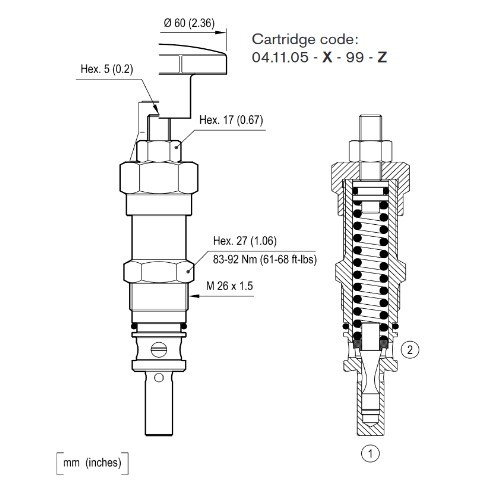

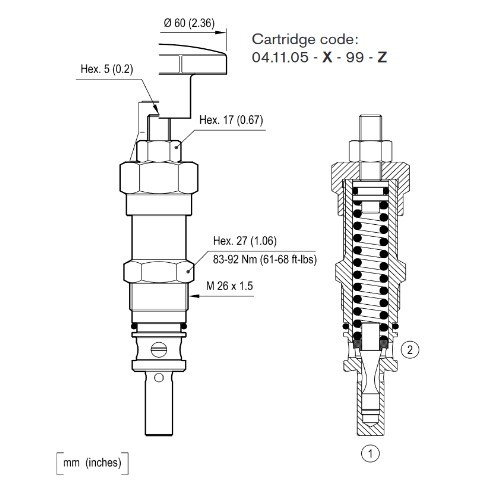

The direct acting pressure relief valve is made up of a spring adjustable by the screw. The conical valve rests on its seat, it is composed of a servant pusher both as a guide and as a damping device when the valve is closed. A channel ensures the internal drainage of the spring. The evacuation of the excess pressure is done in one step. When the circuit pressure exceeds the pressure reached on the poppet by the spring, the poppet rises from its base and releases all or part of the fluid flow, until the circuit pressure is again lower than the pressure developed by the spring. It is important to note that a direct pressure relief valve is recommended for hydraulic circuits developed with a flow rate of less than 100l per minute. Beyond this flow, it will be necessary to go to a controlled pressure limiter, they are also equipped with a valve and a spring, but their operating modes differ.

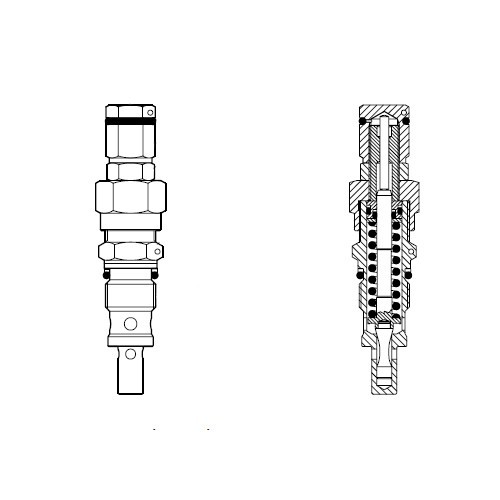

So Pressure relief screw in hydraulic control valves : These valves can be set to maintain a certain pressure. These compact valves are also known as cartridge valves and screw into your mounting block. They open at the set pressure, and then fully open at 20% above the set pressure. They will close as pressure drops, and then fully close when the system pressure falls below the set pressure.

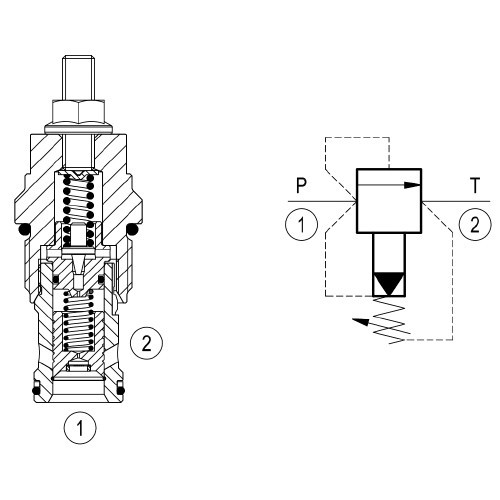

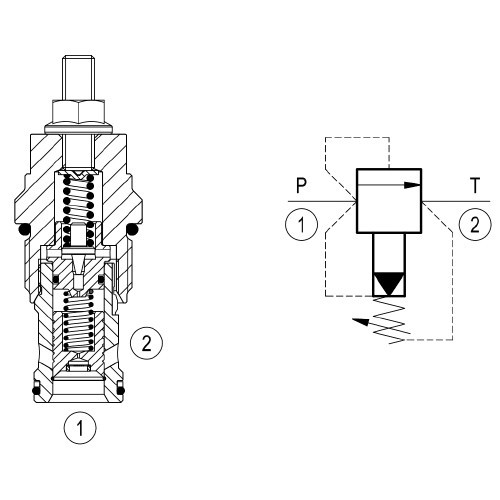

Pilot operated pressure relief valve

The excess pressure is evacuated in two stages unlike a direct acting hydraulic pressure relief valve. The response time of this piloted pressure relief valve is significantly longer. The pilot-operated pressure relief valve is made up of a direct action relief valve, a main block with valve and a retaining spring. The main block having large orifices, the flow evacuated to restore the pressure can be substantial. When the circuit pressure exceeds the pressure exerted by the pilot-operated limiter spring on the valve, it rises from its base and creates an imbalance on the valve of the main block. A reaction time occurs because the pressure continues to rise in the circuit until the force of the fluid on the main valve exceeds the pressure exerted by the retaining spring, which in turn rises from its base. , and releases all or part of the fluid to reach the spring calibration pressure. For high flow rates, generally greater than 100L per minute, the use of a pilot-operated hydraulic pressure limiter is recommended.

There is a variant of a pilot-operated pressure relief valve called a pilot-operated hydraulic pressure relief valve with electrical by-pass control. This is common in hydraulic systems. The principle consists of adding an electrically controlled by-pass distributor.

.jpg)

How to adjust a hydraulic pressure limiter ?

The adjustable pressure limiter

The pressure control made by hydraulic pressure limiting valves limit the pressure of the hydraulic circuit to protect the components. They work by balancing pressure with an adjustable spring force. Each time the pressure relief valve opens in response to a predetermined pressure, it releases excess flow. If the hydraulic relief control valves are not set correctly or monitored carefully, the hydraulic system can malfunction and suffer damage.

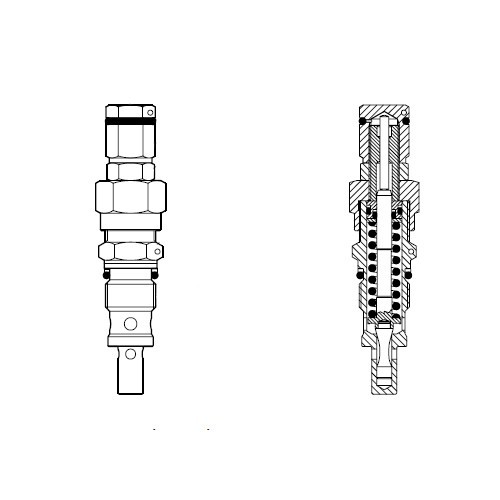

Whether direct or controlled, the pressure is adjusted using a screw-nut system or a knob. Tightening or loosening will ensure that the indicated pressure is not exceeded. The pressurized fluid, for its part, exerts pressure on the valve, in the opposite direction to the spring. An adjustable limiter also has a maximum pressure and flow respected depending on the model chosen, for example, you will not be able to set a maximum pressure of 150 bar on your limiter if it can only accommodate 100 bar.

Pressure relief valve adjustable in detail

We will detail below the steps for adjusting an adjustable pressure limiter and the signs that indicate that it needs to be replaced.

- Consult the machine plans to determine which circuit needs to be set

- Locate the circuit pressure relief valve

- Connect a pressure gauge between the pressure relief valve and the pump

- Loosen the pressure relief valve setting as far as possible. The pressure relief valve is normally fitted with a locking hex nut and an Allen head or hand wheel adjuster

- Start the machine and activate the hydraulic circuit. The pressure reading on the pressure gauge should be close to zero

- Adjust the pressure relief valve by turning the adjuster until the pressure indicated on the pressure gauge reaches the pressure indicated on the machine drawings. This is called the "crack" pressure of the relief valve, i.e. the pressure at which the pressure relief valve begins to open

- Firmly tighten the adjusting lock nut, taking care not to disturb the adjustment of the pressure relief valve

- Stop the machine and let the pressure release.

Some signs of malfunction of the hydraulic pressure limiter

If a pressure relief valve is set but releases pressure before the system reaches maximum pressure, or if the relief valve leaks continuously, there may be a problem with the system. A properly maintained limiter can remain in service for up to 30 years. If you've been testing your hydraulic pressure relief valves regularly, it's likely that something else in your system is at fault. That said, pressure relief valves can fail. It is important to know the signs of a possible failure in order to quickly solve the problem and ensure the safety of your hydraulic installation.

Among the most common problems we can encounter is the impossibility for a pressure reducing relief valve to reach the predetermined pressure. If your system is not reaching the correct pressure, it may be a sign of restrictor failure. In some cases, this can be fixed. If the pressure relief valve has been calibrated to the wrong pressure, it may simply trigger too soon. This can happen when you change the design of your installation. In some cases, technicians forget to recalibrate pressure relief valves. Your technicians can step in and adjust the pressure to solve this problem.

If that doesn't fix the problem and the rest of your system is working fine, it's likely that your reducing relief valve needs to be replaced. After years of service, the limiter can become damaged or eroded by environmental dirt and debris, preventing it from fully closing. This can cause the limiter to pop, i.e. the limiter is not fully open, but opens and closes quickly, preventing it from doing its job properly. When your system cannot reach the determined pressure, you risk experiencing slow production or downtime.

One of the most common problems that we can also encounter is an excessive maximum pressure problem. If your system exceeds the maximum safe pressure, the hydraulic pressure relief valves open to release the additional pressure, ensuring the safety of your facility, your employees and your equipment. If your system is over pressure and your pressure relief valves have not opened, there may be a failure of the relief valve. Contaminants, such as dirt, lint, rust, mud, or even limiter misalignment, can cause the limiter to stick. At this point, you may find that your system is overpressured.

Finally, the hydraulic pressure reducing may experience leakage problems. While the other two malfunctions seem obvious, this last sign is most noticeable when you directly inspect your limiter. Leaks are a problem and can contribute to slower, less efficient production, but they can be harder to notice, as their effect on the overall system can be much smaller. It is partly for this reason that the testing and maintenance of hydraulic pressure relief valves is so important. A pressure relief valve leak is a little more complicated to troubleshoot, as there are many possible causes. It could be the valve, misalignment that prevents reseating after proper opening, or pressure in the system above the valve set pressure.

Sale of hydraulic pressure relief valves

Proper adjustment, inspection and maintenance of hydraulic system safety valves are essential to the operation of a safe installation. A failing pressure relief valve is most often a symptom of a larger problem. In most cases, it is important to examine the "why" of the failure, rather than simply replacing it.

OCGF is a specialist in hydraulics and can offer you a selection of single or double pressure relief valves, direct or piloted, with which you can equip your hydraulic circuits. We have a wide range of proportional pressure relief valves as well as in-line hydraulic pressure relief valves and double-acting hydraulic pressure relief valves. We can also provide you with pressure limiters with manometer.

We have a large stock to offer you of :

- Directional control valve

- Hydraulic selector valve

- Flow divider

- Check valves

- Solenoid coil

- Bosch pressure limiters

Rexroth hydraulic pressure relief valves are recognized for their quality and robustness. A rexroth pressure relief valve ensures the longevity of your hydraulic installations and their safety

If the product you are looking for is not available or is not on our website, just contact us by email or by phone which you find at the bottom of the page.

.jpg)

.jpg)