Hydraulic Check Valve : Choose the Right Model to Secure Your Systems and Optimize Their PerformanceCartridge Check ValveThe hydraulic check valve is an essential hydraulic component found in all hydraulic circuits. It comes in various assemblies such as in-line, insert, or cartridge models. In-line hydraulic check valves are available in si...

Hydraulic Check Valve : Choose the Right Model to Secure Your Systems and Optimize Their Performance

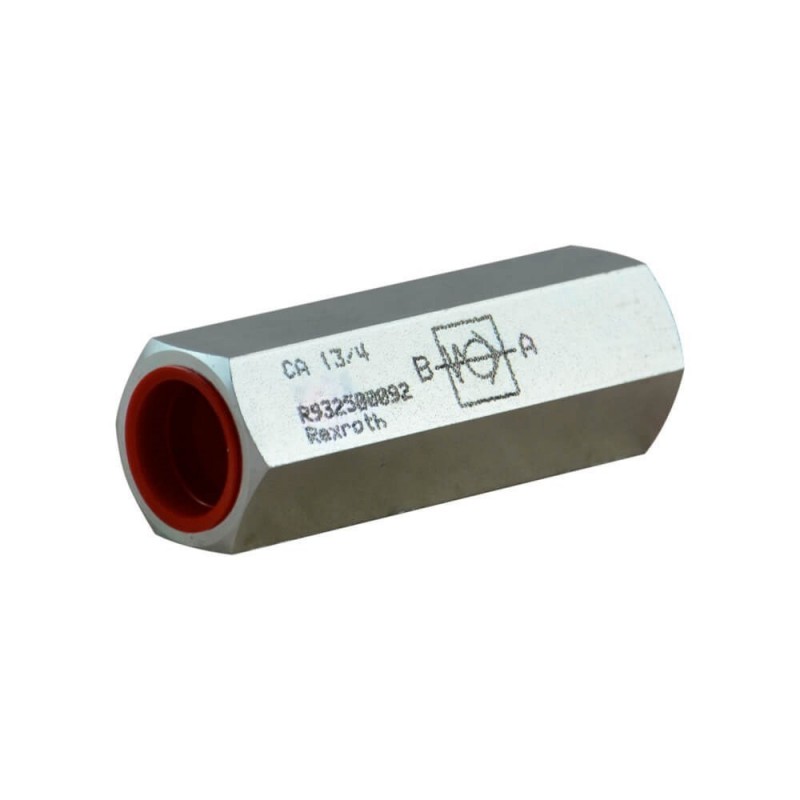

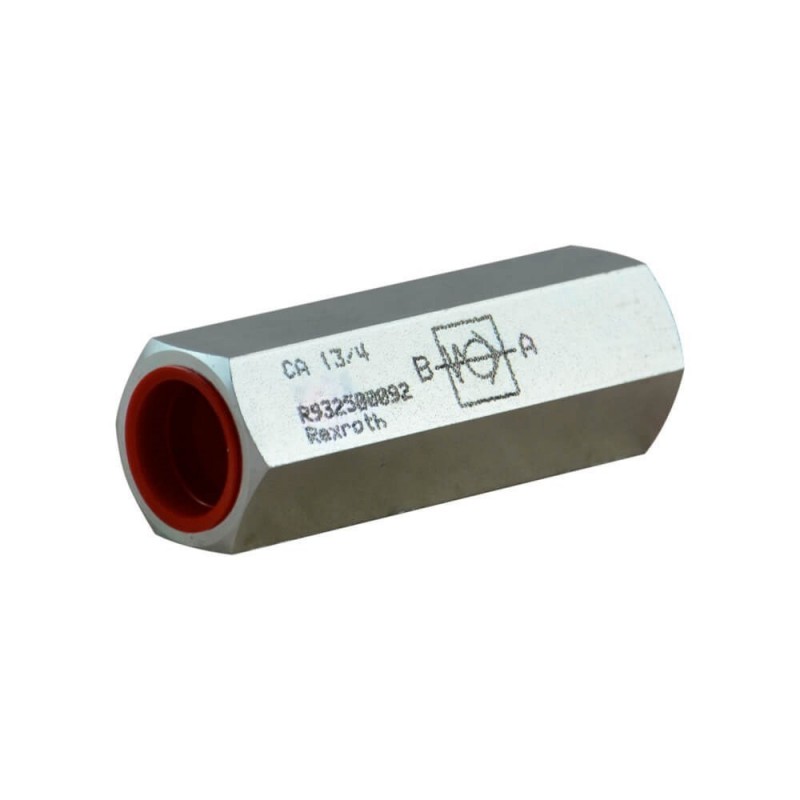

Cartridge Check Valve

The hydraulic check valve is an essential hydraulic component found in all hydraulic circuits. It comes in various assemblies such as in-line, insert, or cartridge models. In-line hydraulic check valves are available in sizes of 1/4", 3/8", 1/2", 1", 1 1/4", and 1" 1/2, with pressure ranges from 0.5 bar, 2 bar, 3 bar, 4 bar, 5 bar, to 8 bar, respectively.

To complement these hydraulic check valves, we manufacture adjustable ranges that allow direct selection of the desired setting. CAB valves are made in 3/8", 1/2", and 3/4". Hydraulic check valves and inserts are also used for functional blocks.

Cartridges include OVC 5 and OVC 6 ranges, from the former FIMMA factory. Today, our hydraulic check valve cartridges feature CA-08-A, CA-10-A, CA-12-A, CA-16-A, or CA-25-A cavities, such as the American HYDRAFORCE cavities, and also the SUN T11A or T17A cavities. Pilot oil control valves are well known to crane manufacturers such as PALFINGER, EIFFEL, and others.

Hydraulic Non-Return Valve : Operation

A hydraulic check valve prevents reverse fluid flow, ensuring the safety and reliability of hydraulic circuits. It works by controlling the direction of flow and preventing any pressure reversal that could damage the equipment or affect its performance. Pilot and adjustable check valves are particularly effective in systems where pressure needs to be precisely adjusted.

The operation of the hydraulic check valve follows a simple rule: fluid can only flow in one direction. As soon as reverse pressure is detected, the valve automatically closes, preventing any backflow.

Different Types of Hydraulic Check Valves

Hydraulic check valves come in various models, each designed to meet specific needs. Among the most popular are:

- 1/4", 1/2", and 3/8" Hydraulic Check Valves: These are used for different pipe and conduit diameters. Choosing the right size is crucial for proper sealing and optimal performance.

- Pilot-operated Hydraulic Check Valve: These models are equipped with a pilot mechanism that allows more precise flow control, ideal for demanding applications.

- Adjustable Check Valve: This type allows pressure settings to be adjusted, making it particularly useful in circuits requiring flexible parameters.

- In-line Check Valve: This model is designed to be installed directly into the fluid line without major modifications to the existing infrastructure.

Applications of Hydraulic Non-Return Valve

Hydraulic check valves are used in many industrial and agricultural applications. For example, in hydraulic braking systems, hydraulic check valves ensure that fluid does not flow back into the pump, preserving braking efficiency. Similarly, in hydraulic cylinder circuits, a hydraulic check valve ensures that fluid does not escape when the cylinder is under pressure. Specialized models are also designed for Bosch injection pumps or industrial systems where protection against backflow is critical.

Hydraulic check valves are therefore used in various industrial, agricultural, and other sectors where controlling the direction of fluid is essential for equipment safety and performance. Key areas of application include:

- Industrial Automation: Used to control fluid flow in complex hydraulic circuits, ensuring the safety and efficiency of automated systems.

- Hydraulic Braking Systems: In heavy vehicle braking systems, check valves prevent fluid backflow and ensure safety.

- Construction Machines: Used in hydraulic systems for controlling the movement of cranes, excavators, bulldozers, etc.

- Agricultural Equipment: Used in tractors, combine harvesters, balers, etc., to ensure effective fluid control in variable working conditions.

- Lifting Systems: Used in lifting equipment such as aerial lifts, cranes, and forklifts.

- Drilling Equipment: In drilling systems, hydraulic check valves prevent fluid backflow under high pressure, ensuring consistent performance.

- Vehicle Hydraulic Systems: Used in applications like power steering, suspension, and transmission systems in vehicles.

- Marine Systems: Check valves are used in hydraulic systems of ships and offshore platforms.

- Energy Production Systems: Used in turbines, hydraulic generators, and renewable energy production facilities.

Hydraulic check valves are essential in many types of machines and equipment where fluid and pressure control are critical for the safe and optimal operation of hydraulic systems.

Installation and Maintenance of Hydraulic Check Valves

Correct installation of a hydraulic check valve is essential to ensure optimal performance and longevity. During installation, it is important to follow the manufacturer's instructions and ensure the valve is installed in the correct direction. Improper installation can lead to leaks or system malfunctions.

As for maintenance, it is recommended to regularly check the valves for wear or blockages. A faulty check valve can lead to pressure leakage, affecting the entire hydraulic circuit. Also, make sure to adjust the valve if using an adjustable model to ensure optimal system operation.

Why Choose Our Hydraulic Non-Return Valve ?

At OCGF, we offer a full range of Bosch and other reputable brand hydraulic check valves. Our products are of high quality and designed to meet the most demanding performance and safety standards.

We provide competitive prices on Rexroth check valves while ensuring robust, reliable products. Additionally, we guarantee fast global delivery so you can receive your products quickly.

Choosing the Right Hydraulic Check Valve : Our Tips

When selecting a hydraulic check valve, it is essential to consider several factors to ensure the chosen model matches your application perfectly. Here are the main factors to consider:

Size

It is critical to choose a valve that fits your installation. Make sure the valve is compatible with the pipes in your hydraulic system.

Examples:

- 1/4" Check Valve: Ideal for small circuits or light equipment.

- 1/2" Check Valve: Common for medium-sized applications or systems.

- 3/8" Check Valve: Suitable for medium-pressure systems.

Operating Type

The valve's operating type determines its ability to regulate flow and adapt to specific system needs.

Examples:

- Pilot-operated Hydraulic Check Valve: Used in systems requiring precise flow control.

- Adjustable Check Valve: Allows pressure settings to be adjusted, ideal for systems with variable pressure.

Mounting

The mounting of your valve must be compatible with your system. Different mounting types are available based on your configuration.

Examples:

Insert Mounting: Easy to integrate into existing systems, often used for repairs or upgrades.

In-line Mounting: Installed directly in the fluid line, common in systems that don’t require major infrastructure modifications.

Cartridge Mounting: Allows replacing only the cartridge without changing the entire valve body, often used for space-constrained applications.

Connection Type

The connection type plays a crucial role in ensuring compatibility between the valve and your pipes or system.

Examples:

- Gas Connection: The valve is designed to connect to gas-threaded pipes, used in some industrial hydraulic systems.

- Metric Connection: More common in European systems, designed to connect to pipes with standard metric threads.

Flow Rate

The flow rate is an important factor to ensure the valve can handle the necessary fluid volume.

Examples:

- Low Flow Check Valve: Suitable for low-capacity systems, such as agricultural or irrigation equipment.

- High Flow Check Valve: Used in large-scale systems, such as construction machinery or production plants.

Maximum Pressure

The maximum pressure indicates the pressure the valve can handle without failure. Ensure the valve can handle your system's maximum pressure.

Examples:

- Maximum pressure 200 bar: Ideal for standard industrial systems.

- Maximum pressure 350 bar: Necessary for high-pressure systems like drilling machines or heavy equipment.

Opening or Operating Pressure

The opening pressure is the pressure at which the valve operates under normal conditions. It should be lower than the maximum pressure but high enough to meet your system's needs.

Examples:

- Operating pressure 0.5 bar: Suitable for standard installations.

- Operating pressure 8 bar: For more demanding applications, such as hydraulic presses or heavy equipment.

Cavity

The cavity refers to the internal space designed for fluid regulation. It should be matched to your system's specifications for optimal performance.

Examples:

- Standard cavity valve: Suitable for general applications.

- Special cavity valve: For systems requiring precise flow control.

Order Your Hydraulic Non-Return Valve Today

Don't leave the safety and performance of your hydraulic systems to chance. Order your hydraulic check valve today and benefit from our expert advice, satisfaction guarantee, and fast delivery. Don't wait, explore our range and choose quality with OCGF.